Responsible sourcing has been steadily growing in popularity and importance for many years, but recent changes in consumer demand and legislation mean that commodities organisations need to be more aware of sourcing issues and may need more robust sourcing and traceability programmes more rapidly than they expected.

As consumer demand for socially and environmentally responsible products continues to grow, organisations are taking note, developing product offerings, and changing investment strategies to meet this demand – and take advantage of the price premium that often results from it.

The greenwashing issue

A major challenge in the environment, social, and governance (ESG) arena is that there are limited widely-agreed definitions of which products are sustainable, or even what comes under the label of sustainability or responsible sourcing. This has led in the past to accusations of “greenwashing”, where an organisation presents an environmentally responsible public image, but this is not backed up by its activities. These accusations can severely damage brand reputations, and with no consensus over what makes a product sustainable, there is the double-threat of organisations acting in good faith being penalised for perceived greenwashing, and of less scrupulous competitors claiming a green premium that they have not earned.

New standards are on the way

In July, the EU Commission released a new strategy that includes a new European Green Bond Standard and an updated ESG taxonomy that aims to prevent the greenwashing issues. The EU Taxonomy will provide clear definitions of what can be considered green to companies, investors and policymakers. The Taxonomy is based on six environmental objectives, including climate change mitigation, water and marine resources, pollution prevention and the protection of healthy ecosystems.

Investors based in Europe will soon have an obligation to disclose how their sustainable funds align to the EU Taxonomy so will be asking these sustainability questions globally, and many other jurisdictions are consulting on their own taxonomies, including Canada, Japan, Malaysia, Singapore, the UK and others. Meanwhile, in France, organisations could already face fines for making misleading greenwashed claims.

Responsible sourcing affects everybody

On top of the general responsible sourcing requirements coming into force, each commodity and asset has its own challenges to address. Oil and energy face challenges around decarbonisation. Agricultural commodities face reputational risks if they cannot live up to their environmental and social responsibility claims, and some face systemic problems such as low wages, or the forced labour practices that are driving brands to avoid Chinese cotton.

The metals supply chain is also facing increased pressure to source materials responsibly, particularly since electric vehicles have focussed attention on supply chain issues such as child labour in cobalt supply chains, and human rights abuses and carbon emissions in aluminium supply chains. As well as industry initiatives such as the LME responsible sourcing requirements, some jurisdictions are considering new compliance requirements for electric vehicle and other battery sustainability, including the UK and the EU.

Responsible sourcing is essential

With the growing emphasis on responsible sourcing, it is becoming more important than ever to understand who supplies your suppliers. Organisations will increasingly be expected to work with their partners to understand their entire supply chain; customers, investors and regulators will all expect commitments to responsible sourcing and the traceability processes to back up these policies.

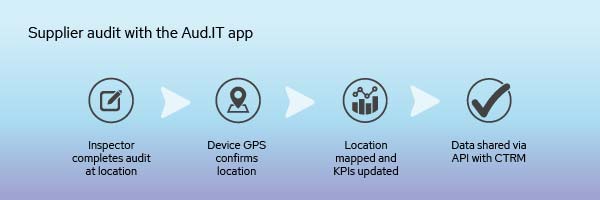

Technology is making this responsible sourcing more feasible and mitigating the reporting burden by making it easier for organisations to monitor their supply chain and share data securely with others. For example, if your CTRM allows you to create API integrations with other systems, any sustainability data for a given lot can be updated automatically as soon as it is received by your organisation, or even directly from your partner’s system.

Aud.IT also allows you to provide benchmarks and KPIs for suppliers, giving them transparency of expectations and incentivising improvements. It can integrate with Gen10’s Commodity.Manager or other CTRM systems to update CTRM records as new information is received from suppliers.

And mapping technology allows you to understand where suppliers, farms, mines and warehouses are based, with satellite imagery, and gives your entire organisation an instant overview of areas of concern.

From CTRM to Commodity Management

Commodity management systems such as Gen10’s CommOS offer more functionality than older CTRM systems. They are designed to allow organisations to manage all aspects of buying and selling commodities, rather than maintaining a narrow focus on risk. Good commodity management systems allow your organisation to trace all goods through your supply chain, managing sustainability documentation from purchase, through transportation and storage, to sale – even when combining, refining or making other changes to stock.

Commodity management systems allow you to manage sustainability data from across your organisation, with each stage of your operations adding more data and building a more accurate picture of your supply chain, without additional reporting tasks for individuals. They also democratise data; sharing it instantly within your organisation for those who need it, whether that is compliance teams monitoring certificates or the front office providing assurance data to clients.

A good commodity management system should also allow your organisation to report on your data however you need to. Gen10’s CommOS allows individuals to create their own dashboards within the system, can integrate with other systems via API to securely share appropriate data with counterparties, and includes customisable reporting options that can be accessed by external parties securely outside of CommOS.

Commodity management technology allows your organisation to move from responsible sourcing as a compliance issue that is addressed through intermittent audits, to responsible sourcing as a core part of your commodity management operations. It enables you to build the processes you need to monitor your supply chain effectively, and to share this information securely and effectively wherever it is needed, with the flexibility to adapt as things change in future.

Want to read more?

Subscribe now for monthly updates

By submitting your details you agree that we can store your data and communicate with you. You can opt out of these communications at any time. Read all in our Privacy Policy.